HANDLING WITH AI-ENHANCED ROBOTIC TECHNOLOGIES FOR

FLEXIBLE MANUFACTURING

HANDLING WITH

AI-ENHANCED

ROBOTIC TECHNOLOGIES FOR FLEXIBLE MANUFACTURING

Project overview

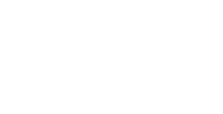

HARTU is an industry-led research project addressing the main challenges of part handling in the manufacturing lines, including gripping, assembly and placement, using innovative and AI-enhanced technical approaches.

The project will apply innovative techniques in industrial case studies to develop tools capable of handling a wide range of products in terms of shape, material and size, enhancing the flexibility, reconfigurability and efficiency of production lines.

Objectives

Latest news

Containerisation in robotics: the HARTU experience

Modern robotics solutions comprise a variety of software and hardware components interacting mutually and seamlessly to provide advanced solutions to the businesses' process optimisation problems. The innovative solutions designed in [...]

Joint webinar: turning real industrial needs into smart, flexible and human-centred solutions

Join us on November 28th at 10:00 CET for the third HARTU online webinar. This event is organised in collaboration with our sister projects MASTERLY, AGILEHAND, and SMARTHANDLE, and promises [...]

From lab to factory floor: testing human–robot collaboration in the food sector

At the end of October, the HARTU consortium reached another key milestone with the real-world testing of its food-sector use case at CentroLazio. With the participation of partners Tekniker (TEK), [...]

HARTU at EFFRA ManuDays 2025: Putting Humans at the Heart of Automation

During the EFFRA Manufacturing Partnership Days 2025 in Brussels, Linda Napoletano from Deep Blue presented the HARTU project, offering a reflection on how innovation in manufacturing must go hand in [...]

Newsletter

Stay updated with HARTU’s latest news and activities

Latest news

Containerisation in robotics: the HARTU experience

Modern robotics solutions comprise a variety of software and hardware components interacting mutually and seamlessly to provide advanced solutions to the businesses' process optimisation problems. The innovative solutions designed in [...]

Joint webinar: turning real industrial needs into smart, flexible and human-centred solutions

Join us on November 28th at 10:00 CET for the third HARTU online webinar. This event is organised in collaboration with our sister projects MASTERLY, AGILEHAND, and SMARTHANDLE, and promises [...]

From lab to factory floor: testing human–robot collaboration in the food sector

At the end of October, the HARTU consortium reached another key milestone with the real-world testing of its food-sector use case at CentroLazio. With the participation of partners Tekniker (TEK), [...]

HARTU at EFFRA ManuDays 2025: Putting Humans at the Heart of Automation

During the EFFRA Manufacturing Partnership Days 2025 in Brussels, Linda Napoletano from Deep Blue presented the HARTU project, offering a reflection on how innovation in manufacturing must go hand in [...]